Flotation with xanthates is currently used by Swedish mining companies in the beneficiation processes of base metals and gold. To provide a more sustainable process, towards a greener mining industry, we have in three sequential research projects financed by Swedish Mining innovation. These projects assessed the potential of replacing current used flotation reagents with lignin particles obtained from renewable feedstocks.

Can the use of abundant renewable feedstocks support a low-carbon-footprint mining industry?

This question initiated a successful research journey, involving the expertise from both academia and industry. For the initial concept, the Biochemical Process Engineering research group at Luleå University of Technology, used their organosolv reactor to develop an eco-friendly production of biodegradable non-toxic lignin particles from forest materials provided by Sveaskog. Boliden Minerals assessed the potential of the organosolv lignin particles to be used as a flotation reagent in a novel sustainable flotation process for copper recovery.

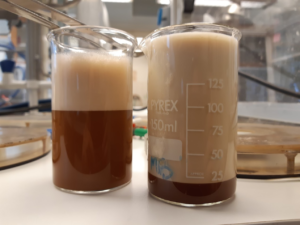

The LIGNOFLOT pre-study was able to demonstrate that the lignin particles had a great potential to enable selective recovery of copper and other minerals in the presence of iron sulphides without the presence of a depressant. The new flotation process using lignin particles is now protected under a Swedish patent, also pending in Europe.

The pre-study was an important opportunity for us to initially test if our idea was relevant and if it was applicable for mining purposes. Based on the positive results and the industrial interest, we continued our exploration of the use of the organosolv lignin particles in the subsequent full-scale project, LIGNOFLOT, now also supported by the expertise of Nouryon.

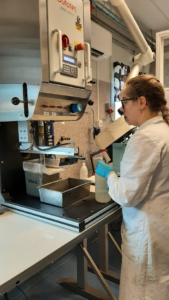

The aim of LIGNOFLOT was to improve selectivity of copper extraction from sulphide ores, based on total or partial replacement of fossil-based xanthate collectors by the developed lignin-based reagent. Starting with development of the organosolv lignin particles through their characterization to their application in the flotation process, the reagent was successfully tested under laboratory conditions with promising results which were verified under semi-pilot plant conditions at Boliden. In the semi-pilot plant trials, use of the organosolv lignin particles in mixture with small concentrations of xanthates led to increased recovery of and selectivity toward copper, while the grade was comparable to the control, where only xanthates were used as collectors. Very small concentrations of organosolv lignin particles (1-5 g/ton) were necessary for improvement of the flotation performance, and the xanthate dosage was significantly reduced (75%). Additionally, it was observed that lime can be removed from the reagent mix while maintaining very high selectivity toward copper. The iron content in the copper concentrates was lower when the organosolv lignin particles were used compared to the flotation performed with xanthates only. Therefore, the organosolv lignin particles have a great potential as sustainable flotation reagent.

“At Boliden, we believe in the power of collaboration. The successful partnership in the LIGNOFLOT project, and now LIGNOMIN, demonstrates the strength of combining complementary expertise. We anticipate that the use of biodegradable and domestically sourced flotation reagents, such as lignin, will pave the way towards a greener and more efficient future for our mineral beneficiation processes”.

Anders Sand, Research Manager, Boliden Mineral AB

Building on the knowledge gained from the LIGNOFLOT project, the subsequent project LIGNOMIN, which started in March 2023, aims to increase the number of lignin sources used for the lignin particle reagent. The project is carried out with the long-term support from Boliden and includes new partners, Bottenvikens Bryggeri and ONar AB. The objective of LIGNOMIN project is to provide a holistic concept for a low-carbon-footprint mining industry by using renewable feedstocks for production of novel biobased flotation reagents that can offer higher revenue by an increased recovery of valuable base metals. More specifically, in LIGNOMIN we will explore the impact of using lignin from abundant lignocellulosic sources, i.e. technical lignins from Nordic biorefineries and residues from the agro-food sector, for production of lignin particles to be used in a new flotation reagent system. An interesting approach is the use of brewery waste, in this case brewer’s spent grain, as a lignin source.

“We at Bottenvikens like to collaborate with others, in LIGNOMIN we get the opportunity to work cross industries and disciplines. We can explore technologies to valorize our waste and find new opportunities to position our SME in a circular economy in the green transition of the north of Sweden”.

Mattias Bergström, CEO of Bottenvikens Bryggeri AB

The lignin reagents will be further studied so that specific tailored particles can be produced and applied to specific ore samples. The organosolv lignin particles performed well when tested at the Boliden pilot and their performance, biodegradability, and toxicity of the unreacted reagents under the continuous flotation conditions will be further verified at the Oulu Mining School´s pilot plant. The project is expected to be completed in 2026 and we hope that the results can support the establishment of a European production line of flotation reagents, which will simultaneously increase the economic impact and lower the environmental impact as well as strengthen the international competitiveness in the sector.

“The funding scheme of the Swedish Mining Innovation has enabled us to explore and demonstrate the industrial feasibility of using biodegradable lignin particle and its potential to increase metal recovery while simultaneously reducing the environmental footprint of the mining sector”.

– Ulrika Rova, Professor and Project Manager, Luleå University of Technology.

Katerina Hruzova, Kalliopi Pavlopoulou, and July Ann Bazar.